Unlocking the Future of Industrial Automation

ADI + Siemens Integrated OPA Testbed at MxD

Demonstrating real-world, multi-vendor interoperability in a live industrial environment.

Open. Interoperable. Intelligent.

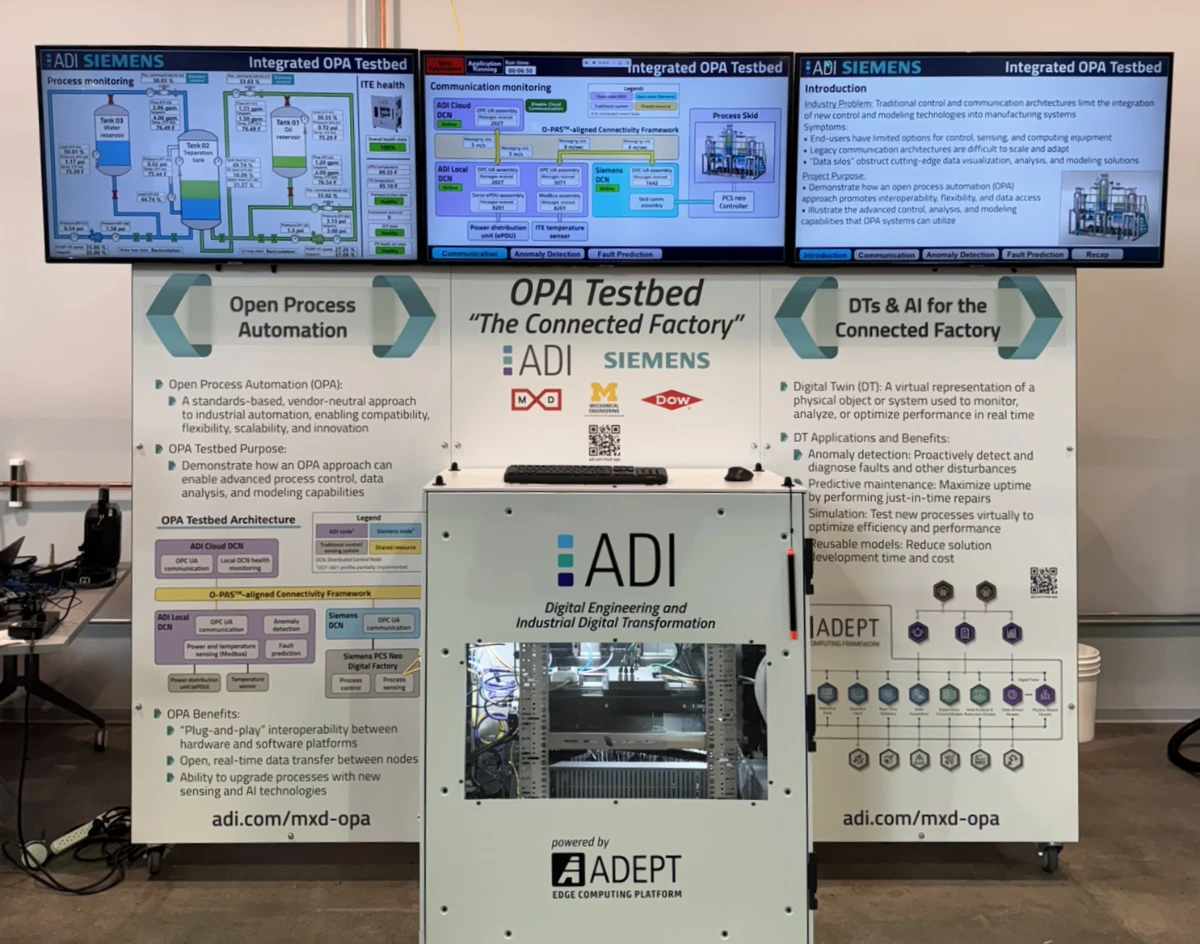

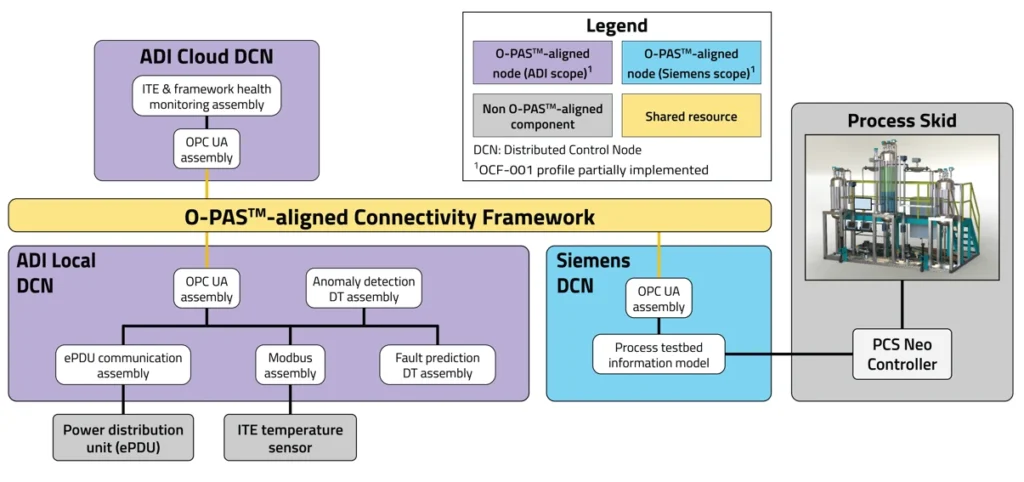

The Integrated Open Process Automation (OPA) Testbed is an innovative automation ecosystem developed through a partnership between ADI, Siemens, the University of Michigan, and MxD. The testbed leverages real-time communication between disparate software platforms, distributed control, and adaptive machine learning models to bring the vision of software-defined manufacturing to life.

Built for the Factory of the Future

Whether you’re a plant manager, CTO, systems integrator, or defense supplier, the OPA Testbed serves as a reference implementation for modern, data-driven manufacturing. It demonstrates how digital engineering principles can be applied today to build smarter, more resilient industrial systems.

This testbed demonstrates:

- A flexible control and communication architecture that supports future updates and enhancements

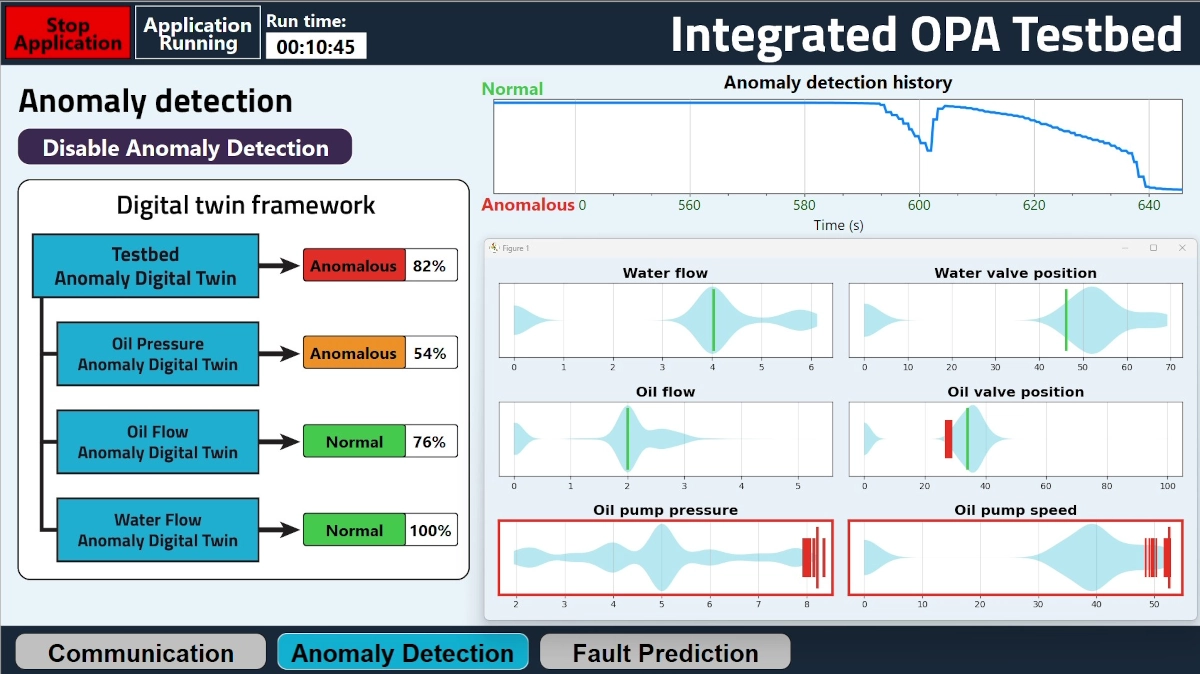

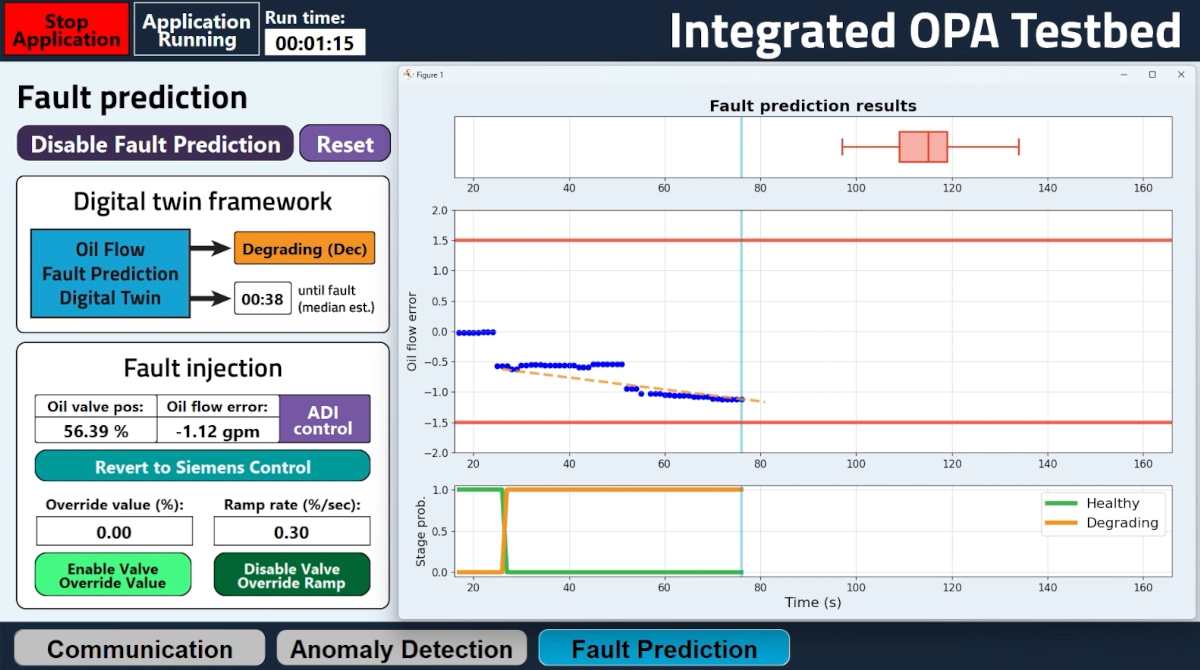

- Digital twins and machine learning models that provide real-time diagnostic and predictive insights, maximizing the value of untapped operational data

- Improved uptime, safety, and operational agility with closed-loop intelligence and flexible system architecture

- Reduced vendor dependency and tech stack rigidity, accelerating innovation and adaptability

This is not theoretical, it’s live and operational on MxD’s factory floor in Chicago.

Why It Matters

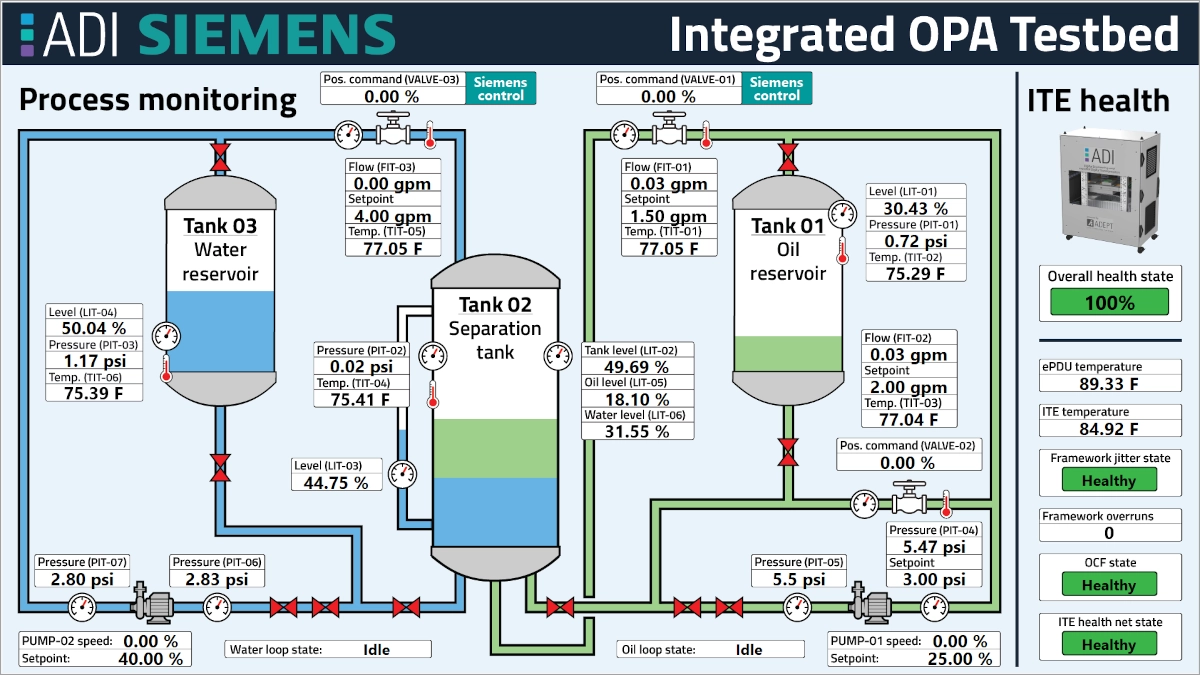

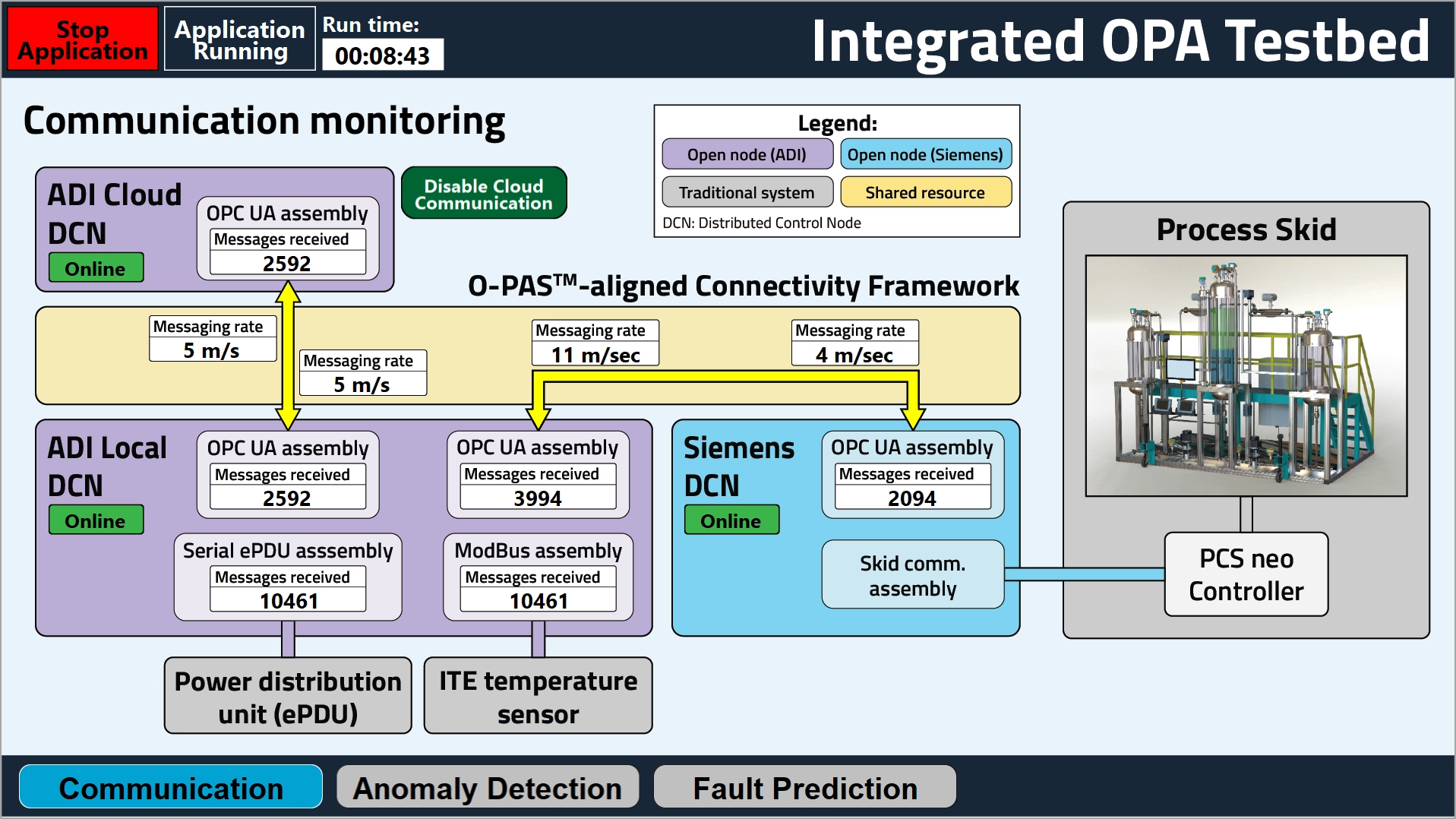

Legacy manufacturing systems are often limited by rigid control architectures, vendor lock-in, and underutilized data. The OPA Testbed removes these constraints to unlock advanced smart manufacturing capabilities. Built on OPA principles, it unites ADI’s ADEPT platform and Siemens’ PCS neo through real-time OPC UA communications. This enables AI-based anomaly detection and fault prediction functions that provide novel insights into process and equipment health.

Collaboration That Drives Innovation

The OPA Testbed is the result of a unique partnership between industry leaders, researchers, and innovators who share a vision for the future of digital engineering. Each organization contributed its strengths, from advanced technology and world-class research to project leadership and integration expertise. Together, they have created a dynamic testbed where new ideas can be developed, tested, and scaled to transform modern manufacturing.

ADI

As the driving force behind the OPA Testbed, ADI brought together the partners and technology that make this project possible. Central to ADI’s role is the ADEPT™ platform, which empowers the testbed to operate as an intelligent, adaptive environment where data fuels discovery. ADI’s applications engineering team leveraged ADEPT to build the testbed’s user interface and to deploy the digital twins that analyze process data to perform anomaly detection and fault prediction. With this project, ADI has not only made the testbed a reality but also set the stage for a new era of predictive, adaptive, and resilient manufacturing.

Siemens

Siemens brought unmatched expertise in automation and control to the collaboration. Their leadership in the testbed’s design and integration created the foundation for seamless data exchange and experimentation. Beyond technical contributions, Siemens identified the process anomalies and faults that are used to illustrate the testbed’s modeling capabilities ensuring the testbed could demonstrate the real-world value of advanced manufacturing intelligence.

MxD

As a national hub for digital manufacturing and cybersecurity, MxD played a critical role in launching and sustaining the OPA Testbed. By providing the physical space, project management, and a collaborative environment, MxD created the conditions for innovation to thrive. The organization also ensures the testbed remains a showcase for the future of manufacturing by featuring it in member programs, presentations, and tours.

University of Michigan

Through its Barton and Tilbury Research Groups, the University of Michigan delivered the academic depth that rounds out the OPA Testbed. Their researchers collaborated with ADI to design and train the machine learning models that power the testbed’s digital twins that allow the system to continuously learn and adapt. By bridging cutting-edge research with practical application, the University of Michigan ensures the testbed remains a dynamic tool for discovery, experimentation, and real-world validation.

Explore the Tech

The Integrated OPA Testbed brings to life a modern digital engineering environment for manufacturing. It demonstrates how open, standards-aligned systems can deliver real-time performance, vendor-neutral interoperability, and AI-powered analytics.

Key Features:

- Real-time, bi-directional OPC UA communication between Siemens PCS neo and ADI’s ADEPT platform

- Purpose-built digital twins for anomaly detection and fault prediction, powered by machine learning models trained on historical datasets

- Automated model retraining processes that leverage live process data

- Scalable, secure architecture bridging local and cloud-based systems

This testbed is not a lab simulation—it’s a working implementation of digital engineering principles. It shows how engineering teams can unify control, sensing, and computing equipment to increase reliability, reduce downtime, and accelerate decision-making across the full product lifecycle.

User Interface

Watch the Presentation

On-Demand

Discover how the Integrated OPA Testbed is redefining process manufacturing. This presentation highlights how open networks and decentralized control unlock greater interoperability, improved data access, and advanced analysis, showing industry professionals the real-world benefits of OPA in action.