Aerospace & Defense Digital Engineering Solutions

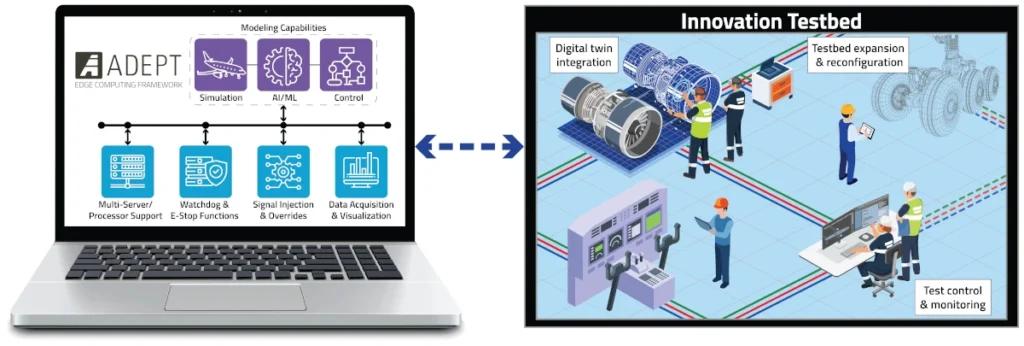

ADI’s ADEPT software is the industry’s leading real-time edge computing platform, offering plug-and-play connectivity, real-time data access, and exceptional computational scalability and efficiency for digital engineering innovations.

The aerospace and defense industry makes extensive use of digital engineering solutions whereby one or more model-based methodologies are incorporated into the product development process to increase the quality of the product and reduce the cost and duration of the product development program. ADI helps the aerospace and defense industry drive digital engineering innovation for greater returns.

ADI’s ADEPT software is the aerospace and defense industry’s leading real-time edge computing software platform for digital engineering solutions. Not only does ADEPT provide plug-and-play connectivity, real-time data access, and model/algorithm execution at the edge, but it also provides unmatched computational scalability and efficiency, in a truly open architecture platform.

Rapid Prototyping Solutions

Innovation in aerospace and defense often involves the development of a system that introduces new technology for specific benefit and involves taking the system through a technology maturation process where the technology readiness level is increased through a series of test campaigns.

Rapid prototyping solutions have become the go-to method for rapidly and cost-effectively performing comprehensive model-based testing to ready a system for flight test, sea trials, field test, etc. Whether developing a new avionics architecture, a more electric airborne system, or a new flight control system, a rapid prototyping platform allows prototype systems to be connected to a real-time, model-based computing environment allowing the system-under-test to be put through highly realistic, normal operating mode and failure mode conditions with simulation-in-the-loop.

Benefits of Rapid Prototyping

A rapid prototyping test platform is a significantly lower-cost testing platform as compared with the main alternative, e.g. flight test, sea trials, field test, etc. A rapid prototyping test platform also allows for the types of failure mode and edge-of-the-envelope testing that would be unsafe to perform in, for example, flight test. Well-implemented rapid prototyping solutions will make heavy use of test automation to minimize the test operation effort, allow for fully-automated test campaign execution, and support the use of multiple rapid prototyping test rigs to perform parallel testing, e.g. simulated flight test, dramatically reducing the technology maturation lifecycle time, dramatically reducing test operation labor, and maximizing return-on-investment.

Innovation Testbeds

Innovation testbeds elevate technology readiness levels by integrating physical and virtual assets into a platform for rapid experimentation, testing, and validation.

What is an Innovation Testbed?

Industry leaders in the aerospace, defense, and manufacturing sectors continually strive to optimize their operations and adapt to new circumstances, often by taking advantage of emerging technologies such as advanced control strategies, digital twins, and artificial intelligence. Innovation testbeds allow organizations to validate the most uncertain elements of these technologies so they can be deployed with confidence. A well-designed test platform combines physical equipment and communication links with virtual assets, giving researchers the ability to perform simulations, prove component compatibility, and verify performance benchmarks in a manner that is faster and safer than real-world tests.

ADEPT + Testbeds

ADI’s ADEPT edge computing platform has been specially designed to support innovation testbeds that are open, interoperable, and adaptable. ADEPT projects use synchronized data dictionaries to compile information from different subsystems and manage communication between computing nodes. The data in these centralized repositories can be visualized for users with live plotting tools and exported in several common formats. Support for a diverse set of communication protocols allows organizations to integrate components and models from multiple sources into a new testbed or augment an existing testbed with new computing capabilities. Multiple system configurations can also be saved within an ADEPT framework, so physical and virtual components can be added, swapped, or rearranged as needed for different test setups. These features make ADEPT a best-in-class software package for research and development efforts across several industries.

Benefits/ROI

When designed and built well, innovation testbeds deliver productivity, efficiency, and risk mitigation benefits that provide a return on investment that far exceeds their development and operating costs. These platforms can be used across many industries to automate experimental procedures, data collection, and report generation, accelerating testing and validation processes. The ability to combine physical equipment with simulated/emulated systems reduces setup costs and facilitates frequent, targeted testing of individual components. The risk of damaging physical equipment is also greatly reduced, lowering repair and replacement costs.

Organizations can leverage these time and cost savings to deploy products and processes more quickly and to further mitigate the risk of design and interoperability flaws through expanded testing programs. Additional physical and virtual tests under conditions that are not feasible in the real world can suggest design changes that improve system performance and identify problems that would incur long-term support costs. Over time, these benefits provide a competitive advantage through stronger margins, more resilient operations, and the ability to quickly adopt next-generation technology.

Aircraft Testbeds

Well designed and built aircraft testbeds provide a power digital test environment where an aircraft’s electrical, hydromechanical, and flight characteristics can be holistically evaluated, seamlessly interfacing real and simulated aircraft hardware and subsystems.

What is it?

A key foundation in modern, successful aircraft programs globally, aircraft testbeds have evolved into distinct types, each with a specialized scope and focus:

- Cockpit Integration Facility – With high-fidelity visual systems and a representative flight deck, the Cockpit Integration Facility is used for pilot-in-the-loop human factors testing and the evaluation of flight characteristics as aircraft control laws are developed and refined. Generally, the first testbed developed in an aircraft program, the CIF enables valuable pilot feedback early in the design cycle.

- System Integration Bench – The SIB provides a focused environment for integrating and verifying avionics systems. Systematic testing in the SIB validates avionics system software builds, data bus architectures, and interface compatibility before progressing to higher-fidelity testbeds.

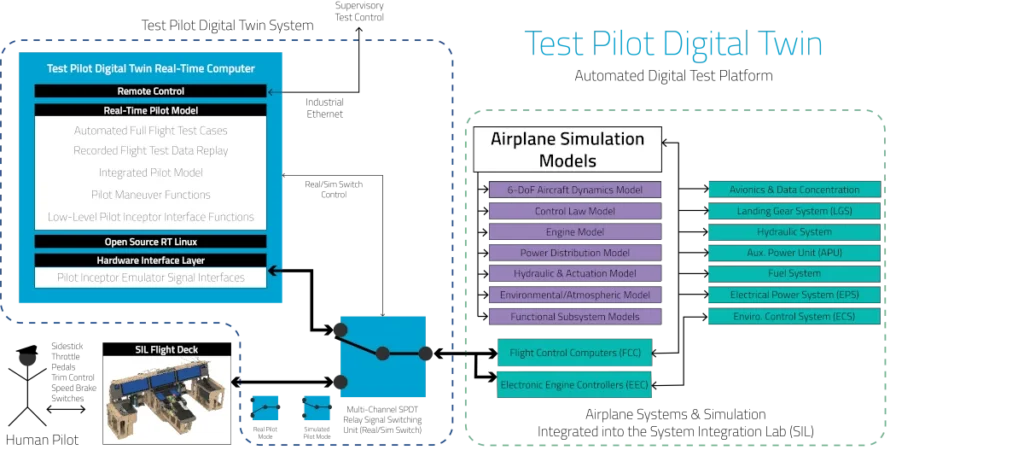

- System Integration Labs (SIL) aka. Integration Test Facility (ITF) – The ITF is where aircraft subsystems from multiple suppliers are brought together and validated as a complete electrical system. It provides a representative environment to connect flight controls, environmental systems, propulsion controllers, sensors, and avionics subsystems through the same wiring, data buses, and interfaces used on the aircraft. By combining real aircraft hardware with simulated model assets, the ITF verifies electrical and logical compatibility, ensuring that subsystems operate together without conflict.

- Iron Bird – The Iron Bird is a full-scale, ground-based test rig focused on hydromechanical systems. It replicates hydraulics, flight control actuators, landing gear, and braking systems under realistic force-loading conditions. This setup allows validation of control laws against real mechanical system responses.

Benefits / ROI

The advanced testing capabilities provided by modern aircraft testbeds result in significant reductions to program cost, schedule, and risk. Issues that are difficult or impossible to detect prior to subsystem integration can be identified early in the lab environment, well before costly flight testing. Automated test campaigns enable round-the-clock utilization and repeatable regression testing. Test scenarios that would be considered high-risk in flight test can be explored safely in the lab environment. For program stakeholders and potential customers, aircraft testbeds also serve as a tangible demonstration of progress, showcasing advanced technologies and integration maturity long before the first flight vehicle is ready.